1.

|

3.

|

4.

|

5.

|

7.

|

2.

|

6.

|

8.

|

9.

|

11.

|

13.

|

15.

|

16.

|

10.

|

12.

|

14.

|

Explanations for each

picture are below.

|

17.

|

19.

|

21.

|

23.

|

25.

|

18.

|

20.

|

22.

|

24.

|

Click on any picture to

link to a larger image.

|

26.

|

28.

|

29.

|

31.

|

32.

|

27.

|

30.

|

|

|

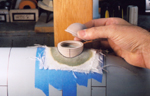

| 1. The diver's hatch is shaped from a block

of RenShape material. |

| 2. The hull curve is lofted from the area of

the diver's hatch using five layers of 7oz fiberglass cloth, the

RenShape block carved to fit, and a master "puck" made from

which to vacuum form the actual hatch. |

| 3. The drop-pen compass is used again to mark

the circumference of the main hatch on layers of fiberglass clothe which

will serve as the flange around the conning tower. |

| 4. Note the conning tower in foreground. This

was created from RenShape on a lathe and hollowed out to the final

diameter. |

| 5. Details of drop-pen compass and main hatch

flange after removal from hull. |

| 6. Tools used to trim and shape the

fiberglass flange. |

| 7. Fitting the conning tower combing to the

hull . . . |

| 8. . . . and the dome. |

| 9. Port hole flanges for the conning tower

were turned on a lathe and, with the brass piece still in the chuck,

holes drilled to later accept rivets. |

| 10. Returned to the lathe, the porthole

flanges are parted into individual pieces. |

| 11. Parts of the diver's and main hatch and

conning tower before assembly. |

| 12. Main hatch. |

| 13. Preparing the propeller shaft for the

process of creating the shaft and blades and mounting on the hull. This

shaft is one of the conjectural elements on the Alligator model. The

1861 version, of course, had no propeller since it used oars for

propulsion. During the 1862/63 refit, the propeller was added--but were

the rudders moved to accommodate it or was the shaft extended beyond the

rudder? Adding a propeller extension seems the simplest solution . . . |

| 14. After alignment, the prop shaft is

pressed against the stern with carbon paper sandwiched in between to

show any points that do not align. |

| 15. Diagram of the propeller shaft and rough

pieces of the propeller blades. |

| 16. Final prop blade is mounted vertically

and the mold container set over it (clear cylinder to right) and sealed

with clay. Silicon rubber is poured in and allowed to solidify. |

| 17. After removing master blade by slicing

the mold along its vertical sides, the mold is resealed with rubber

bands, and Alumilite resin is poured into the cavity through the prop

shaft that had been allowed to protrude through one end of the mold.

Also shown are a number of the poured blades. |

| 18. Prop blades are mounted onto the hub at

identical angles by affixing each one to the shaft while it lies atop a

bed of clay. |

| 19 & 20. Views of the final propeller and

shaft. |

| 21. Mounting the final propeller and shaft

onto the hull. |

| 22. Figures, hatches, portholes, propeller,

and rudders. |

| 23. Plans and parts for the diver's helmet. |

| 24. Diver and helmet parts. |

| 25. Final helmet. This is the Miller-Dunn

style helmet, which is not evidenced officially until after the Civil

War. The standard deep sea diver Siebe helmet would have been too large

and cumbersome for the diver to have used in moving through the hatch.

Another alternative is a leather helmet first created in Paris for

firemen to use in smoky buildings; de Villeroi may have been aware of

it. The US Navy also experimented with a leather diving helmet, but,

officially, not until 1863. |

| 26-30. Views of the diver as he nears

completion. Married to the air hose is the lifeline that anchors the

diver to the submarine. |

| 31 & 32. Marking out the buoyancy tanks

with the drop-pen compass. |